AQUATOP® VIRTA

AQUATOP® VIRTA is a premium quality paint formulated for factory use on exterior joinery such as window frames and doors of both standard species and modified woods.

How do you make sure a topcoat can handle the toughest weather and still look good?

AQUATOP® VIRTA is our latest innovation in industrial topcoats for exterior wood. It was developed by our dedicated R&D team in Denmark: Christina Normann, R&D Manager, Susanne Havndrup, R&D Specialist, and Nette Berendtsen, R&D Laboratory Technician.

AQUATOP® VIRTA is designed to withstand the toughest climates and maintain a beautiful finish at the same time. But how does this really happen from market demands to final testing? Let's take a look behind the scenes.

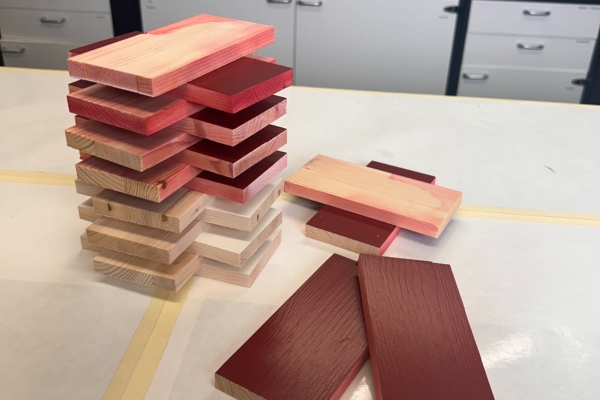

The journey of AQUATOP® VIRTA began with careful lab testing. The team was focused on ensuring that the product would not only withstand but excel in extreme conditions. One important focus was on the product’s blocking properties.

Blocking properties are what keep the coating from sticking to itself or other surfaces when doors or windows are stacked. At the laboratory they test and simulate real-world situations. To make sure AQUATOP® VIRTA passed this test, the team dried the coating for 4 to 6 hours, then stacked the samples together with high pressure at varying temperatures and humidities. The results showed that AQUATOP® VIRTA could be handled without any issues, no matter the season or climate.

Lab tests were just the beginning. To ensure AQUATOP® VIRTA would last, the team exposed it to outdoor conditions in one of the toughest environments. The samples were placed at a 45-degree angle facing south, where they experienced direct sunlight, rain, frost, and wind for a full year. This helped confirm that the product could withstand harsh weather while still looking good.

"We test the painted samples by placing them at a 45-degree angle to get maximum exposure to sunlight, rain, frost, and wind. This is much harsher than how windows are typically installed at a 90-degree angle at the end-customer's location. This way, we push the product to its limits to see if the surface holds up", says Susanne Havndrup, R&D Specialist.

"Standard testing under these tough conditions lasts for one year before we start testing the product at customers’ sites. But our testing doesn’t stop there. Even after the product is on the market, we keep testing it to meet international standards, like those in France and the Netherlands. They require longer exposure periods", Susanne continues.

By following these thorough testing methods and meeting international standards, AQUATOP ® VIRTA not only meets the needs of different markets but also shows that it can last and perform well in real-world conditions.

AQUATOP® VIRTA was also designed to work well with other Teknos products through many different paint systems. This means it can be used with layers like impregnation to prevent fungus, primers and fillers.

This system approach is crucial because wood is highly vulnerable to environmental factors.

"When wood is used outdoors, fluctuations in humidity and temperature can lead to cracks and splits if it is not protected against the weather. When the moisture content in wood then reaches 20%, fungi can start to grow", says Christina Normann, R&D Manager and elaborates:

"Our products are designed to repel water, protect against UV rays and prevent damaging fungi. That’s why we emphasize the strengths of system treatments. Depending on the substrate and the system, we use multiple layer system. For example, we can start with an impregnation product to protect against fungi, followed by a primer for a full and smooth surface and preventing discolouration. Finally, the topcoat adds colour, shine, and the last layer of protection against the elements."

"So when we test, we use a system treatment to ensure our products are compatible with other products we recommend, offering a complete solution", Christina continues.

During the development of AQUATOP VIRTA, one of the key challenges was making sure the topcoat could resist water shortly after being applied.

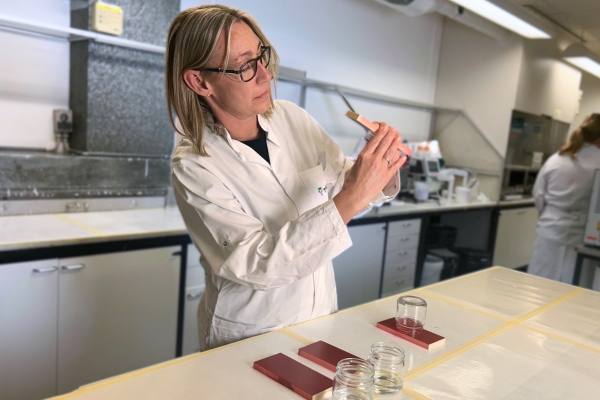

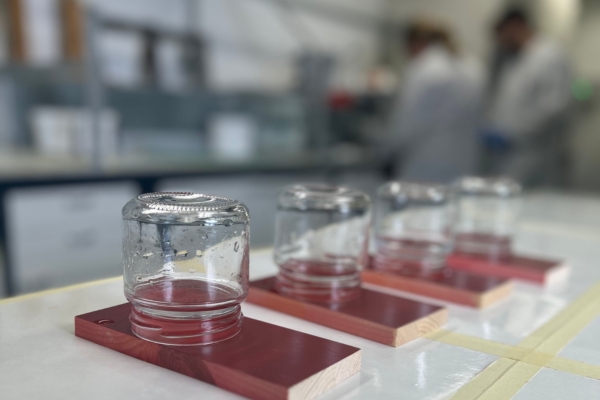

To test this, the team used the "water-cup test." Water was placed on the coating after it had dried for 6 or 24 hours, and the surface was checked for swelling, blisters, or discoloration to see how well it handled water.

The tests were done under different conditions: low temperatures with high humidity, moderate temperatures with normal humidity, and high temperatures with high humidity. These conditions were chosen to simulate different climates and drying environments to make sure that the product could handle a wide range of real-world situations.

Through these tests, the team learned that the coating becomes exceptionally water-resistant after only a few hours, regardless of the environment it was exposed to.

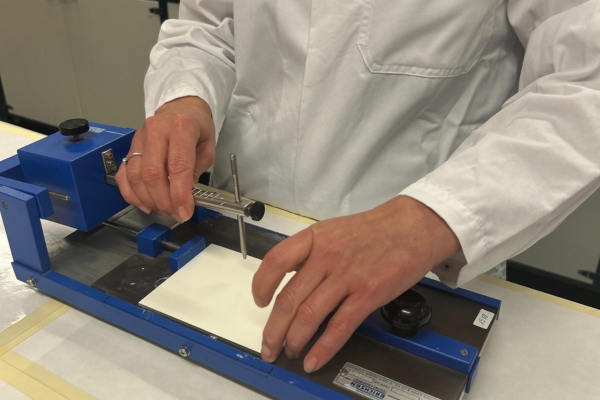

To test toughness of the product, the team performed the scratch test. The test evaluates how well the coating resists scratches and stays intact. The test was conducted after various drying times to demonstrate what happens at each stage - for example, from the window manufacturer's production line, through transport, to the end customer.

Nette Berendtsen, R&D Laboratory Technician explains:

"When the window manufacturer handles the coated elements, such as installing hinges, the surface may get damaged. During transport, windows and other coated surfaces can also get scratched or damaged. Once they reach the end customer, the coating needs to resist everyday wear and tear, like scratches from keys or tools. We simulate these situations to test how tough and scratch-resistant AQUATOP® VIRTA is."

AQUATOP® VIRTA is now ready for the market, backed by thorough research and testing. The hard work and expertise of Susanne, Nette, and Christina are reflected in every can of AQUATOP® VIRTA.

AQUATOP® VIRTA is built to perform in tough conditions. This high-quality topcoat is made to meet the needs of both manufacturers and end-users, keeping surfaces protected while looking good.

In the heart of our R&D department in Vamdrup, Denmark, three passionate women: Christina Normann, R&D Manager (left), Susanne Havndrup, R&D Specialist (middle), and Nette Berendtsen, R&D Laboratory Technician (right), have been the driving force behind the creation of AQUATOP® VIRTA.

Susanne, the R&D project leader, aimed at creating a durable product that can perform consistently in any climate. With Christina leading the R&D team and Nette contributing her specialized expertise, the three formed a solid team.